8th European Thermoforming Parts Competition

Originality, creativity, mould complexity and technical ability will be the judging criteria in order to promote advanced design and developments from a structural innovation perspective.

The award winners will be presented at the conference.

The essential points of the European Thermoforming Parts Competition are the design-oriented application of materials and the successful combination of technical innovation and design quality.

The aims of the European Thermoforming Parts Competition are to highlight potentially new design-orientated market opportunities by combining the innovative with the traditional and by pushing back the current boundaries of material performance.

We look forward to receiving your contribution. For questions about the Conference or the Parts Competition, please visit the ETD website.

Michel Py

Chair Parts Committee

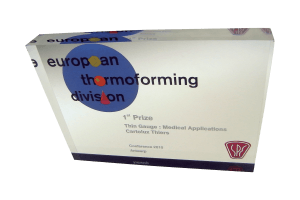

Winners of the 7th European Thermoforming Parts Competition 2018

For the 7th time, in 2018 the European Thermoforming Parts Award once again highlighted applications selected by the jury at the recent European Thermoforming Conference in Rome, Italy, from 14 – 16 March 2018.

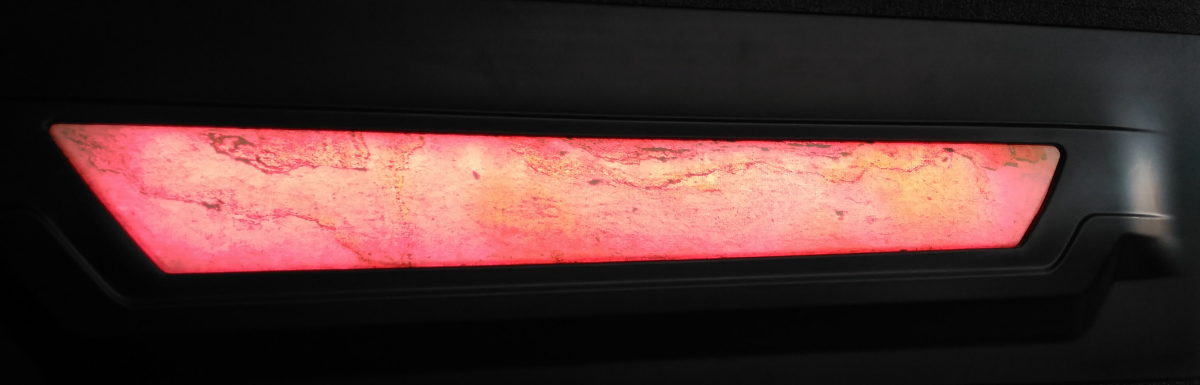

PART DIMENSIONS: 430 x 60mm

MATERIAL TYPE:MATERIAL GAUGE: 1mm

SHEET SUPPLIER: Confidential

MOULDMAKER:. Walter Pack

This 1mm thick film is made of natural stone layer adhered to a transparent thermoplastic. They have been thermoformed and injected with a transparent thermoplastic, thus enabling backlighting effects.

The judges particularly appreciated the innovation for stone thermoforming. This original application by its translucent or opaque declination in the automobile cladding make the piece a unique product enhancing the innovative spirit of our industry.

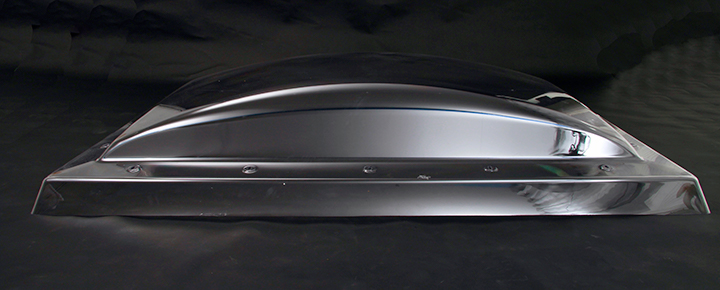

PART DIMENSIONS: 800 x 600 x 200

MATERIAL TYPE: Casted Acrylic, glass clear

MATERIAL GAUGE: 6mm

SHEET SUPPLIER: Altuglas

MOULDMAKER: Tooling Holland

The mould is made out of steel and tempering is set up like an injection mould furthermore it is chromed on all the spots where the sheet is touching the mould (only 10% of the surface). Chrome plated steal tool and plug with several thermoregulation systems and air support. Weight tool over 600kg and plug over 200kg. After the milling process the product has to be complete flat in a specified plain and complete glass clear. The processing is something between forming and pressing the material in a particular shape.

The judges particularly appreciated the perfect transparency and material distribution of this premature baby incubator cover. This cover dismounts the superb quality that can be obtained on important parts in thermoforming in front of an injected part.

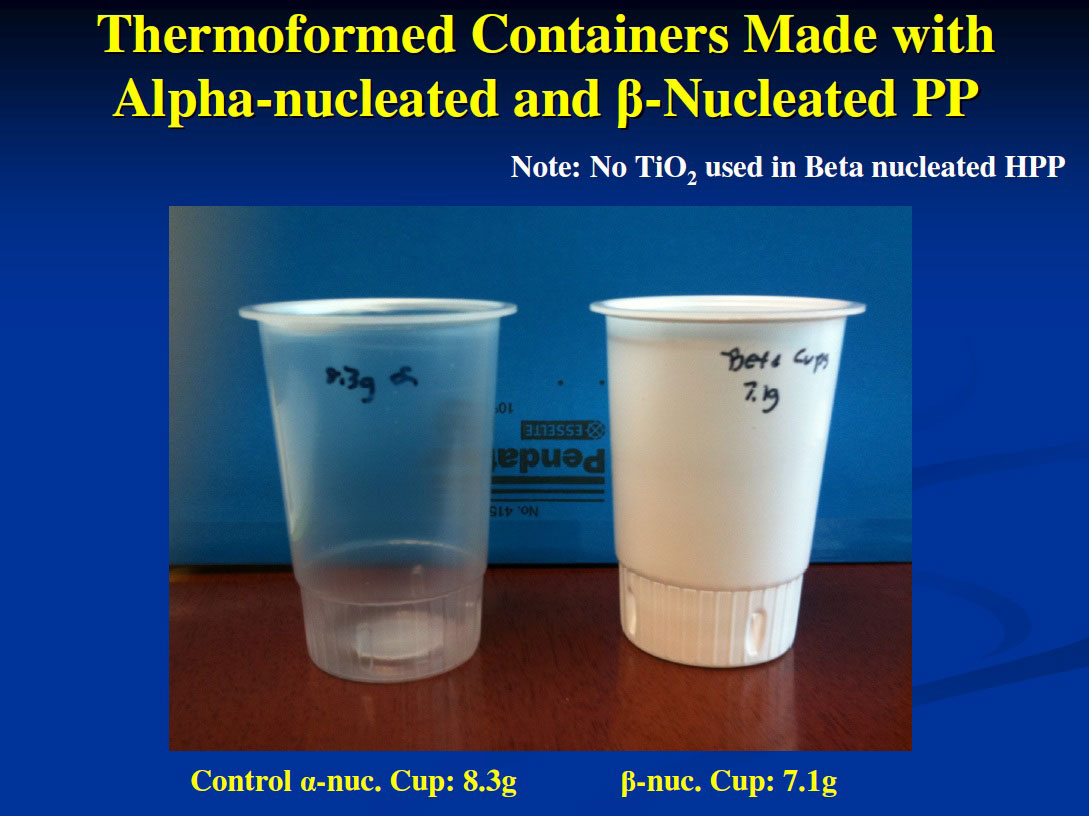

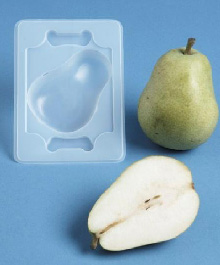

PART DIMENSIONS: 19*24cm

MATERIAL TYPE: NX™ UltraClear™ Polypropylene

Glass-clear transparency

Sealing in freshness

Lightweight & productivity gains

Hot filling, retort & microwave ability

Stiffness & impact strength

Recycling & sustainability

The judges particularly appreciated the weight reduction of the 14g to 12g tray, or-16%. The tray PP has kept the transparency of the original tray in PET and now allows to be used in the microwave oven or for hot filling with same stiffness and impact strength.

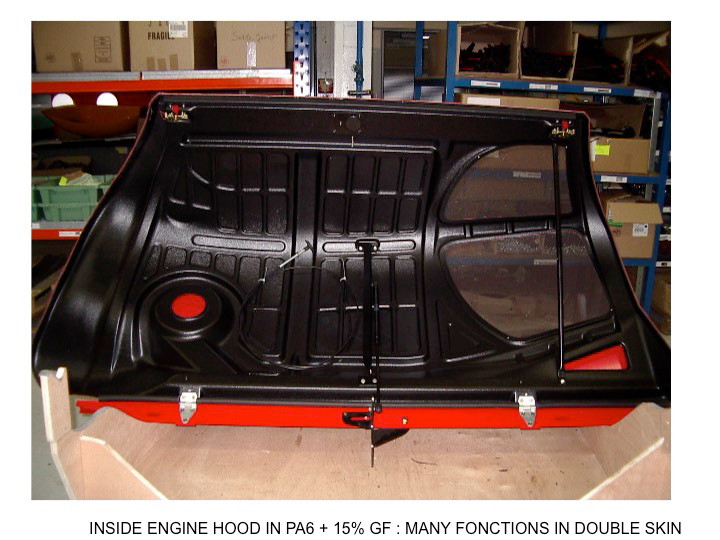

PART DESCRIPTION: A partition between the cargo compartment and the passenger compartment

PART DIMENSIONS: 1663 x 1408 x 540 mm

MATERIAL TYPE: ABS

MATERIAL GAUGE: Thick

The judges particularly appreciated the high optical quality – visible from both sides. Very complex shapes – high pre-blow (600mm). This part must hold the glued glass – high security part according to ISO 27956